INDUSTRIAL OASIS – Quality Innovation United has had the ground-breaking of the Lightion Campus, its first project in Myanmar.

The project locates in the heart of Thilawa Special Economic Zone covering 31,000sqm total building area. The project was commissioned as the electronic manufacturer Lightion’s flagship South East Asia production and R&D facilities. It includes a production space for precision manufacturing as well as new R&D offices. With closely controlled internal climate for the equipment and storage. A higher performance envelope design is achieved compared to the existing requirements and abundant indoor and outdoor social spaces for its staff members. It will set new standards for advanced production facilities.

The masterplan consists of 2 buildings, separated by its functions. The production centre employs a structural system based around a 36 X 24 metre structural-grid which is larger than usual planning module developed to maximise the planning flexibility of the internal spaces. Much like a contemporary airport space the structure design is featured with 32 tree-like branching steel columns – which effectively reduced the roof span by 2/3 and decreases the total material tonnage. The sloped roof surface is sliced into several hierarchies and supported by the tree-columns, forming a striking silhouette within its surrounding landscape. The envelope form was also inspired by the vernacular architecture of Myanmar, creating stepped skylights to reduce the complex’s lighting energy consumption.

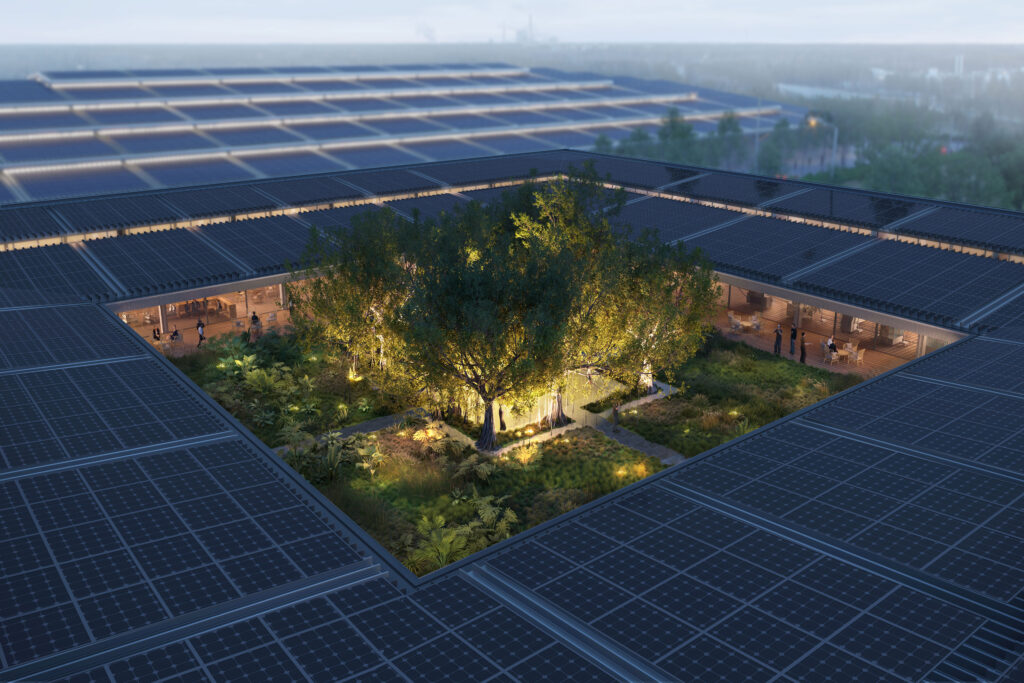

The office is annexed to the west of the production making the circulation between the two buildings fluid. A rainforest central courtyard is at the heart of the building to allow everyone working here access nature and to bring in daylight for the building. A deck under the shaded veranda around the courtyard will provide a perfect place for informal meetings and collaboration between the people that work here. Intimate pocket garden spaces are also formed in between the production and office buildings.

The project aims to become a leader in sustainable campus in Myanmar. Photovoltaic panels are installed on all roofs that will provide 60% of the annual energy consumption. Service ducts are planned under the slab with floor-mounted diffuser so that the cooling demand is lower than typical factory buildings. Solid external walls with punched in slot windows will reduce heat gain while allowing diffused light, water collection from the roof can be recycled for building uses. Skylights are introduced at pitched roof to bring in daylight, and the featured “Oasis Courtyard” provides a view to greenery from workspace. A large, covered deck in the front of the building will be an event space for the local festivals such as the Water Pouring Festivals.

‘Its presence promises to not only add a feature to the SEZ but also invigorate the local economy, offering employment opportunities, stimulating business growth, and attracting investment. It will help to position the community at the forefront of the global manufacturing landscape.’

Quality Innovation United

Program – Industrial, Manufacturing, Office

Location – Thilawa SEZ, Myanmar

Scope – Master plan, Architectural Design, Interior Design

Status – Construction